What Does Premier Aluminum Llc Mean?

Table of ContentsPremier Aluminum Llc for BeginnersRumored Buzz on Premier Aluminum LlcThe Definitive Guide for Premier Aluminum LlcThe Ultimate Guide To Premier Aluminum Llc

(https://pxhere.com/en/photographer/4463036)Using reduced expense and unqualified vendors can create top quality problems, and threw away time and money in the long run. To assist you with the process, here are some points to consider when choosing the appropriate metal spreading vendor.

A firm that just utilizes the financial investment casting process will certainly try to offer you on why that procedure is best for your application (Casting Foundry). What if using the sand casting process is best for you and your demands? Rather, try to find a provider that provides a variety of casting procedures so the very best option for YOU is selected

If functioning with a single resource for every one of your casting needs is essential to you, the supplier needs to be varied in its capacities. When incorporated with various other integrated abilities, this can aid streamline and press the supply base. When selecting the best spreading supplier, mindful factor to consider should be provided to top quality, solution, and rate.

Some Known Incorrect Statements About Premier Aluminum Llc

Purchasers progressively choose casting suppliers that have machining capabilities. This can avoid problem if defects are uncovered during machining. If a 3rd party is machining, it may lead to "finger-pointing" about that is at mistake. Is it a casting issue or a machining problem? If the casting supplier uncovers a concern during machining, the problem is fixed quicker with no disagreement over whose mistake it is.

What do you need from your casting distributor? Are you looking for someone to just supply a metal part to your doorstep or do you require much more?

Others will certainly go beyond the letter of the PO to help you save time and money. Do you have demands for both ferrous and non-ferrous alloys? Some factories are minimal or specialized. Ensure the distributor can fulfill all your product or alloy requirements to get rid of the requirement for numerous vendors.

More About Premier Aluminum Llc

Research study the vendor's web site. Talk to a sales rep or company partner.

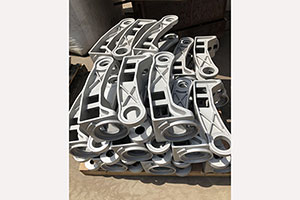

Aluminum is likewise light-weight and has good rust resistance, making it suitable for applications where weight and sturdiness are very important factors. Additionally, light weight aluminum spreading is a cost-efficient approach of production, as it needs much less energy and sources than other techniques. Iron spreading, on the various other hand, includes putting molten iron right into a mold and mildew to create a wanted form.

Some Of Premier Aluminum Llc

Iron casting is likewise able to stand up to high temperature levels, making it ideal for usage in applications such as engine components and industrial machinery. Nonetheless, iron spreading can be much more expensive than aluminum spreading due to the higher cost of resources and the energy called for to melt the iron. When determining between aluminum casting and iron casting, it is necessary to take into consideration the certain demands of the application.

In verdict, both light weight aluminum casting and iron spreading have their own unique advantages and disadvantages. There are three sub-processes that fall under the classification of die casting: gravity pass away casting (or permanent mold casting), low-pressure die spreading and high-pressure die spreading. To obtain to the completed item, there are three primary alloys used as die casting material to choose from: zinc, light weight aluminum and magnesium.

Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!